The Worlds Largest Small Foundry |

|

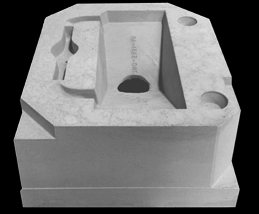

We build in quality and repeatability from the initial pattern layout through final casting inspection Rigging is done using computerized software to insure your parts are free of shrink, tears, and cracks. Patterns are mounted in cope and drag boxes to run on the latest automated molding equipment for quality castings and short lead times. We incorporate the latest technology in our IMF "Fast Loop" molding line with PLC controls. It gives us the ability to produce a wide range of molds each day with minimum labor. The mixer has a digital "Smart Pump" system for consistent mold properties. Reclaimed sand is used judiciously to reduce cost and meet environmental demands without compromising surface finish or mold strength. |

|

|

|